On November, 14th, two dissertations have been presented at “Il trasporto degli alimenti fra logistica ed e-commerce“. These dissertations were prepared from two students within a partnership between the Food Supply Chain Center (Department of Industrial Engineering, University of Bologna) and OITA (Osservatorio Interdisciplinare Trasporti Alimenti). Along with the introduction of these studies, the FSC center presented some new topics of research.

Here we provide a synthesis of our speech.

Speakers: Alessandro Tufano and Andrea Gallo, Ph.D. Students at UniBo.

Topics:

- FSC – Food Supply Chain Center

- Quality management – monitoring environmental stresses

- A fine wine’s case study

- Warehousing Center at UniBO

- StoreOptimizer and LaneOptimizer (Decision Support System at UniBO)

- LogiTransport Center at UniBO

- Presentation other DSS at UniBO

- Distribution Network Planning with climate-driven approach

FSC – Food Supply Chain Center

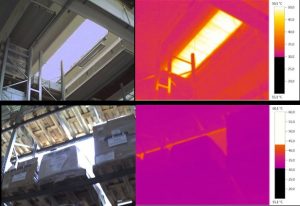

We focused our discussion on the quality traceability and quality assessment conducted in our laboratory. Here we perform the following activities:

- Tracking shipments with on-board data loggers.

- Monitoring environmental stresses during distribution

- Lab simulation of transport conditions in climate rooms.

- Packaging prototyping.

- Planning and scheduling delivery operations in response to climate conditions.

- Chilling and cooling control along distribution operations.

- Monitoring temperature experienced by the load also in different location within the same container.

We presented the newest activity conducted in the laboratory by the Food Supply Chain Center. It consists in the assessment of vibrations monitored on three axes. This allow us to assess the mechanical stresses along with the environmental stresses. We are preparing a shaking table to recreate in our laboratory the stresses experienced by the load to study new packaging solutions. We have already monitored many shipments, including multimodal distribution to study how different vehicles affect the mechanical solicitations.

These studies can reveal how products’ quality and their organoleptic properties are affected by distribution and highlight the new challenges enabled by the distribution of perishable products, especially food products. Environmental and mechanical stresses should be considered to set up a correct e-commerce distribution in order to deliver products to the consumers with the expected degree of quality.

Warehousing Center – Bologna University

In our Warehousing Center, we create advanced models and tools for:

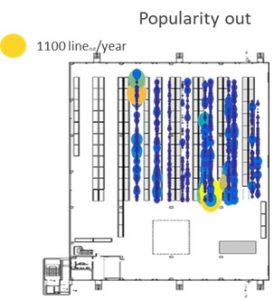

- Storage allocation and storage assignment strategies (e.g. correlated storage assignment)

- Travel time and personnel need minimization

- Unit load and less than unit load storage systems

- Order picking system design and optimization

- Plant layout

- Automated storage and retrieval system (AS/RS)

- Simulation and scheduling of storage and retrieving activities.

- Low temperature

- Storage system design for beverage, bakery, or other food processing industry.

- Design order picking systems (OPS) with order batching and zoning.

With the use of sensors, we can monitor the temperature and humidity in each single location in a warehouse. This allow us to know the exact locations more exposed to extreme environmental conditions. Products (e.g. food or pharmaceutical) that are more sensible to temperature and humidity can be put in the most favorable location, reducing quality losses during storage. With our quality degradation models, we could estimate the residual shelf life of each product in the warehouse and to know if it can be stored in a location or not. We are able to include the weather forecasts in our models and to know exactly the impact of adverse environmental conditions on the warehouse. We can prevent the choice of location that will experience extreme temperature conditions for products that can’t be stored at that environmental conditions.

This allow us to know the exact locations more exposed to extreme environmental conditions. Products (e.g. food or pharmaceutical) that are more sensible to temperature and humidity can be put in the most favorable location, reducing quality losses during storage. With our quality degradation models, we could estimate the residual shelf life of each product in the warehouse and to know if it can be stored in a location or not. We are able to include the weather forecasts in our models and to know exactly the impact of adverse environmental conditions on the warehouse. We can prevent the choice of location that will experience extreme temperature conditions for products that can’t be stored at that environmental conditions.

LogiTransport Center – Bologna University

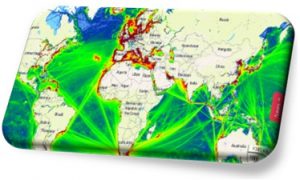

Our department developed many tools and methodologies for the optimization of the distribution phase.

These tools provide support for:

- Strategic planning of distribution networks and logistics infrastructure.

- Network design modeling and optimization.

- Low carbon driven forward-reverse supply chains (e.g., packaging recovery).

- Vehicle-routing in urban and rural context.

- Multi-scenario analysis of carbon trends in supply chain decisions.

- Planning perishable products shipments.

- Decision Support Systems aiding the design of sustainable delivery networks.

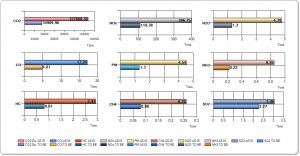

Our tools allow us to quantify the environmental impact of the distribution network, not only by quantifying the CO2 emissions. Our tools are able to quantify all the harmful emissions of the distribution strategy, load per load.

Our recent researches are focusing on the development of integrated models and tools for a climate-driven approach. We think that climate must be considered in the decisional process, as it determines food losses and the energy and cost requirements for refrigeration. As for the warehouse, our models include weather forecasts and environmental conditions in decision support systems for the management of food supply chain networks. These models integrate each logistics aspect, from the production of raw materials, the processing and packaging phase, the storage conditions and the distribution along each stage of the supply chain to optimize the total costs and the total energy consumption for the supply chain. Providing information about the actual network, from the location of each node, to product’s characteristics, vehicle and packages availability and the big data collected by companies, along with weather forecasts, our tools can optimize the network. The results of this optimization consist in the suggestion for managers of what is the best decision to take from the logistic point of view in each stage of the supply chain. This includes scheduling production, processing, storage and distribution, choosing the packaging solution and the transport modality, the best temperature set-point for refrigerated containers and for refrigerated warehouses.

We included climate conditions in our models and tools because they concur in determining the quality of the products delivered to the final consumer and the total energy required for refrigeration. Costs for refrigeration can become predominant for high perishable products, so they can’t be neglected in a proper optimization of the supply chain network.

The availability of such tools and models could help the companies to reduce the environmental and economic impact of e-commerce and enable the fresh food deliveries with the respect of quality standards. These tools support the delivery of perishable products in good conditions for the final consumer, both in the storage and in the distribution phase, aiding companies to perform correctly the logistic activities, economically and environmentally sustainable and delivering products that meet the consumer expectation of fresh and healthy food.